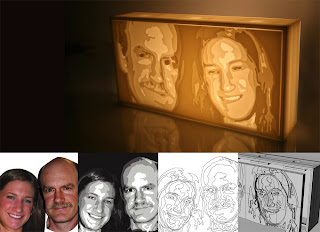

Personal Fabrication Concepts: Illuminated Photobox

Sarah Owen's Illuminated Photobox Sarah’s display begins with a digital photograph. This photograph is transformed into a topographical relief surface. The brightest portions of the photo are the thinnest section and the darkest areas are the thickest sections. This 3D data is converted into surfaces and fabricated using an FDM machine. When light is transmitted through the semi-translucent display the photograph appears as areas of dark and light. Every display can be unique, depending on the photo. Her final FDM part is about 8 inches wide.